Environmental Protection

Greenhouse Gas Emissions Management

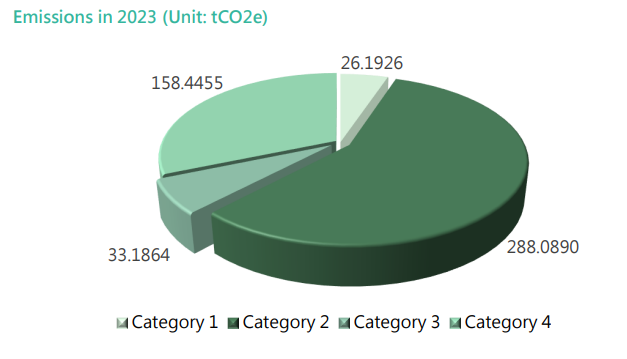

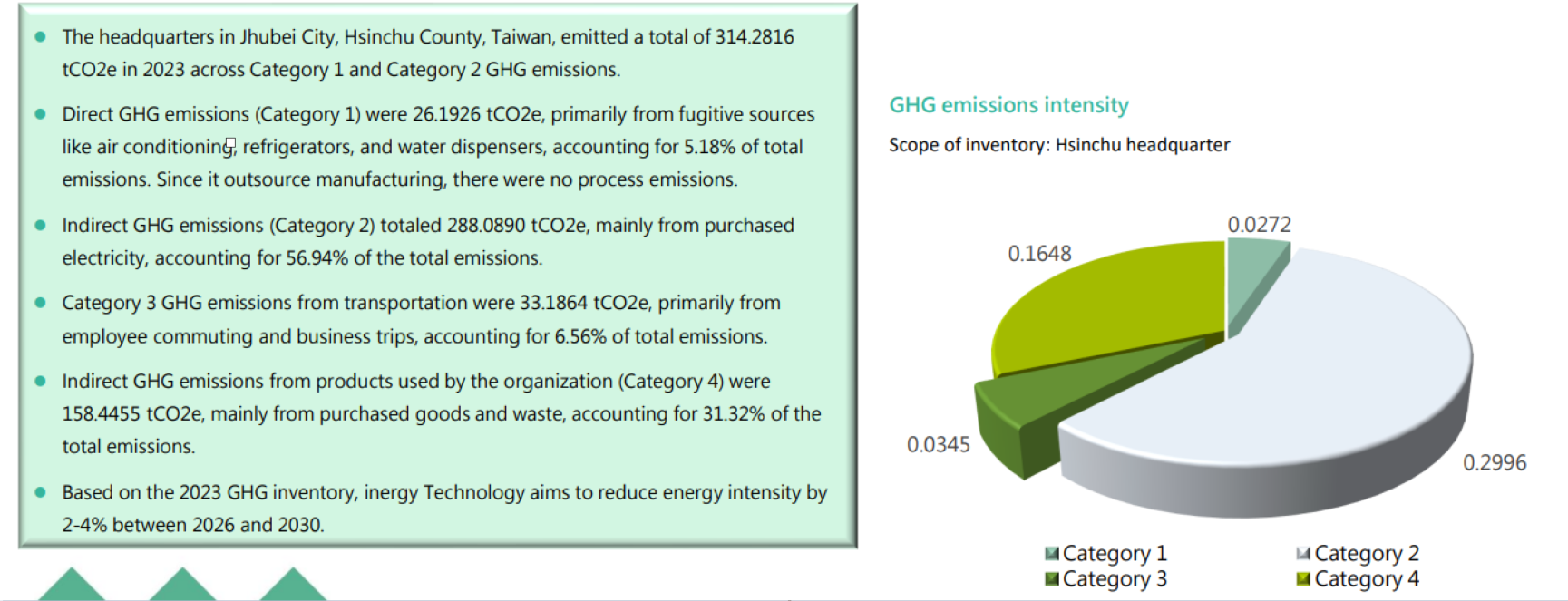

To enhance risk assessment and management, inergy Technology will conduct a GHG inventory in ISO 14064-1:2018 in 2023, with third-party verification in 2024. 2023 will be the base year for its inventory convering direct GHG emissions (Category 1), purchased electricity (Category 2), upstream transportation (Category 3), and raw material purchases and wastes (Category 4). This inventory will be updated annually, and the improvement targets will be based on annual reviews.

| GHG Emissions Per Year |

Category 1 (Unit:tCO2e) |

Category 2 (Unit:tCO2e) |

Category 3 (Unit:tCO2e) |

Category 4 (Unit:tCO2e) |

Total (Unit:tCO2e) |

|---|---|---|---|---|---|

| 2023 (with 3rd party verification) |

26.1926 | 288.0890 | 33.1864 | 158.4455 | 505.914 |

| 2022 | 35.0697 | 315.3872 | 4.2139 | 1.373 | 357.444 |

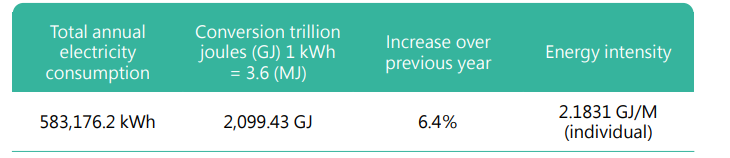

Energy Efficiency

Energy Intensity

Water Resources Management

| Year | Total Water Consumption (Unit : kWh) | Water Intensity |

|---|---|---|

| 2023 | 1,944.10 | 2.00215 |

Waste Management

inergy Technology will ensure that all staff strictly follow waste and recycling practices to enhance resource recycling and minimize general household waste, thereby reduing resource consumption.

| Year | General Business Waste (Unit:ton) |

Recycle (Unit:ton) |

General Waste (Unit:ton) |

Total (Unit:ton) |

|---|---|---|---|---|

| 2023 | 0.439 | 1.0763 | 0.532 | 2.0473 |

Objectives And Indicators

- GHG emissions:

-

- With a base year of 2023, it conducts its GHG emissions verification. With regard to the scope of inventory of its Taiwan headquarter (subsidiary not include), following international standard ISO 14064-1:2018.

- The results of GHG inventories are regularly disclosed annually, improvement targets are set and the performance will be reviewed annually.

- In 2023, the GHG inventory data shows a 1% reduction in energy intensity over the past three years.

- Energy management:

-

- Office lighting is managed by sectors, with lights turned off for 30 minutes during lunch breaks.

- Employees are advised to turn off air conditioning and lighting in unused areas and to set air conditioning temperatures between 26-28 degrees to minimize energy waste.

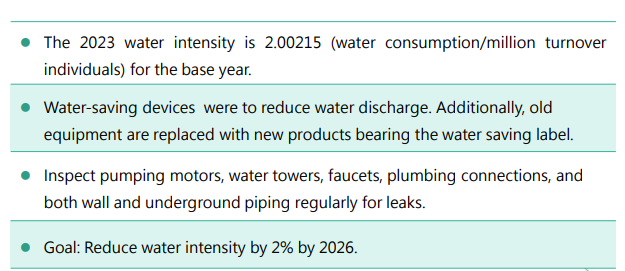

- Water management:

-

- It has a wastewater recycling facility, where waste water is treated at the park's wastewater treatment facility before being re-discharged, minimizing its impact on the water supply.

- It promotes water conservation by installing water saving faucets to replace old equipment. It also conducts regular inspections of pumping motors, water towers, faucets, and piping for leaks.

- In 2023, total water use was 1,944.10 kWh, with a water intensity of 2.0215 kWh per million turnover. This reflects a 1% reduction in water intensity over the past three years.

- Waste management:

-

- Wastes mainly consist of domestic wastes, engineering experimental materials and computer peripheral wastes, and there are no hazardous wastes from production.